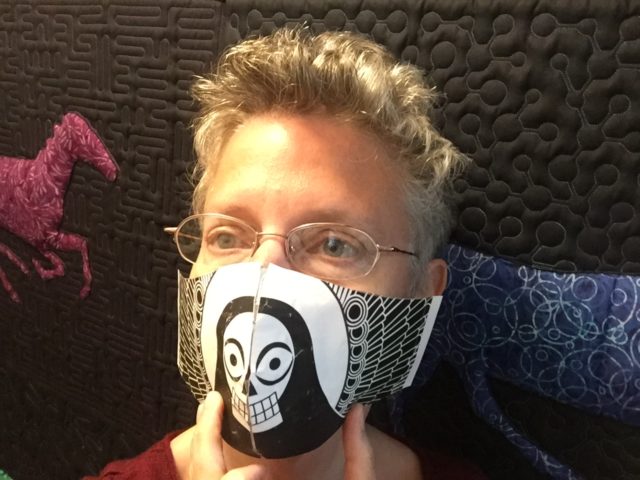

UPDATE: Momz just sewed the first mask prototype!

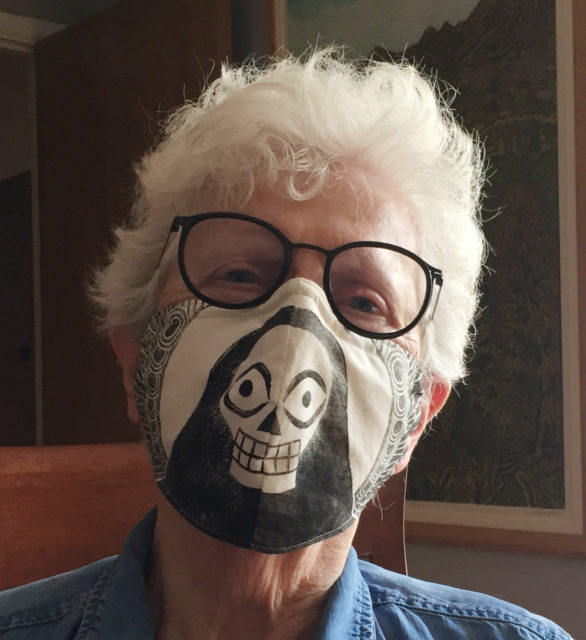

Here she is modeling it:

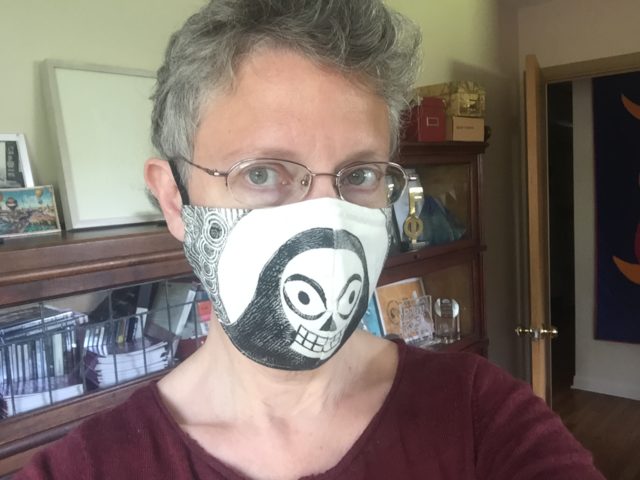

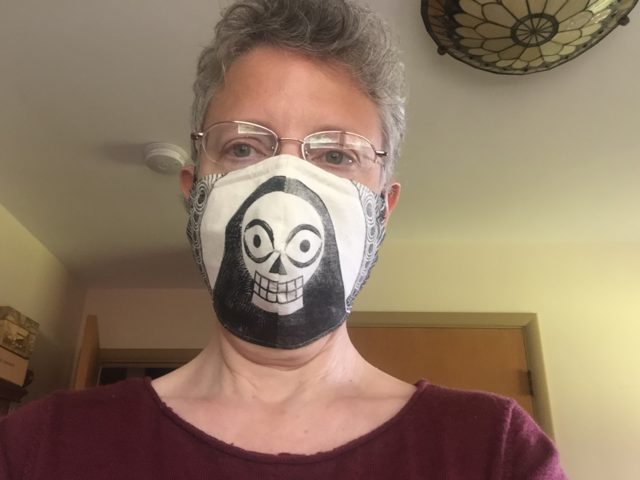

Here I am modeling it:

We look similar, right? Must be that huge Angel O’ Death covering our mouths and noses.

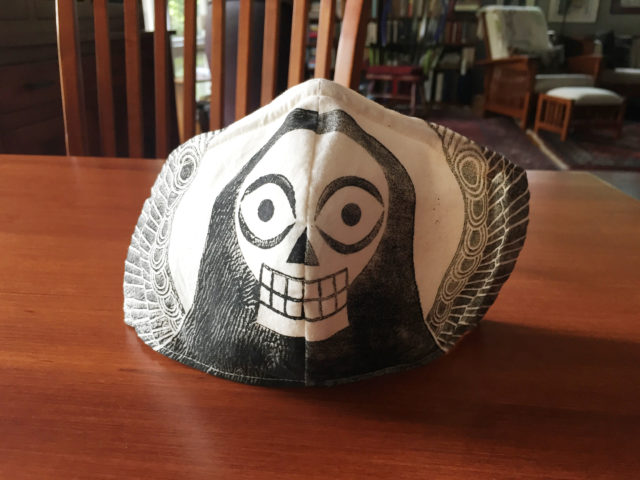

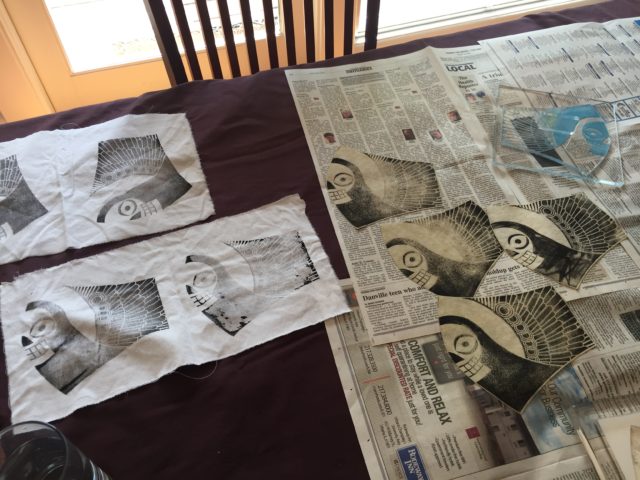

This mask is sewn from the unbleached pre-cut cloth:

Even though I got better ink impressions on the bleached white sheet, in the end we couldn’t use it because it was too soft and floppy to work with. It was literally from an old white sheet I cut up when it got holes in it. The pre-cut is PaleGray Labs’ quilting cotton, which is stiffer and crisper and easier to cut and sew. In the end, though, the off-white cream color has a nice worn look with the hand-print ink texture, and looks as stylish as any mask can be on the face.

More tests to follow.

*******

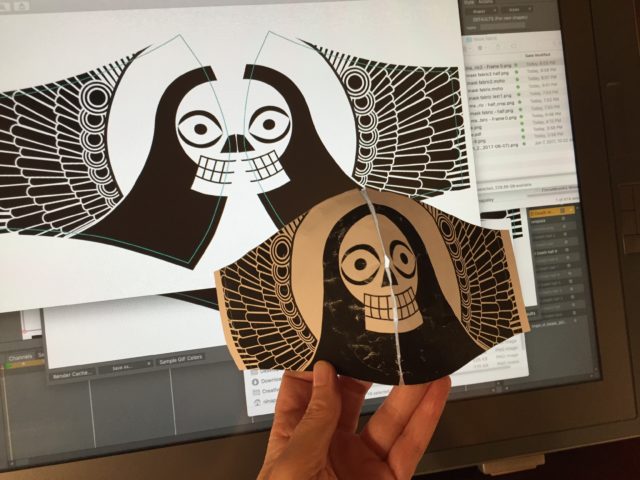

A few days ago, Theo Gray implored me to design fabric for the high-end masks he’s producing here in Urbana Illinois, using his laser cutter to precision cut the fabric components. The Angel O’ Death was an obvious choice, so I got designing:

Because the mask has a curved center seam, the art had to be distorted. I don’t have a single “distort” button (but there are very nice point distort tools in Moho) so I went by instinct. The paper test here is scratched up because I turned it inside-out after taping, which crinkled it a bit.

Now, how to get it printed on fabric? In the past I have used Spoonflower, but they currently have a 15+ day three week delay. Plus the size has to be accurate to fit the masks, and it’s really hard to get that right with Spoonflower, especially given the uncertainty of laundry shrinkage. Because my design was black and white, I realized it could be silkscreened!

But we’re in the midst of a pandemic, so when I called the local screenprinter no one answered the phone. I emailed them but still have no response. Then I thought, “why not block print this sucker?” After all, I’ve used a laser cutter to make Angel O’ Death block prints before:

But where to find linoleum blocks in the midst of a pandemic? Theo doesn’t like using wood in his cutter because it “gums it up.” He prefers acrylic. So I thought, “why not block print using acrylic?” So Theo made these:

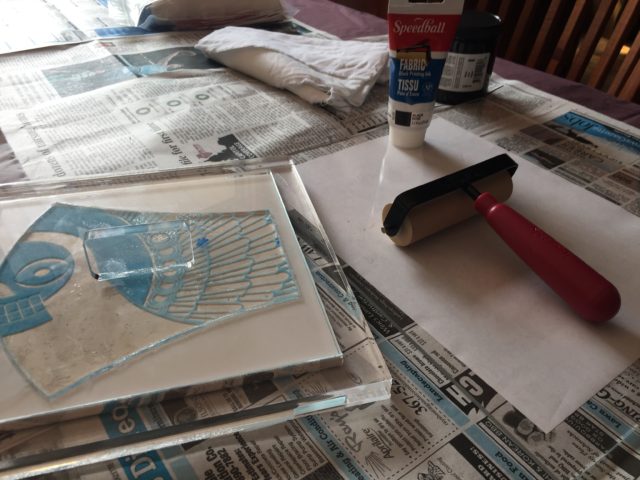

I was able to get screenprint fabric ink and a brayer from the local big box chain art store, by ordering online and getting local pick-up; I got special block print fabric ink from the local local art store, once they finally answered their phone (no pickup, so I got the $5 home delivery). This morning, I did my first tests.

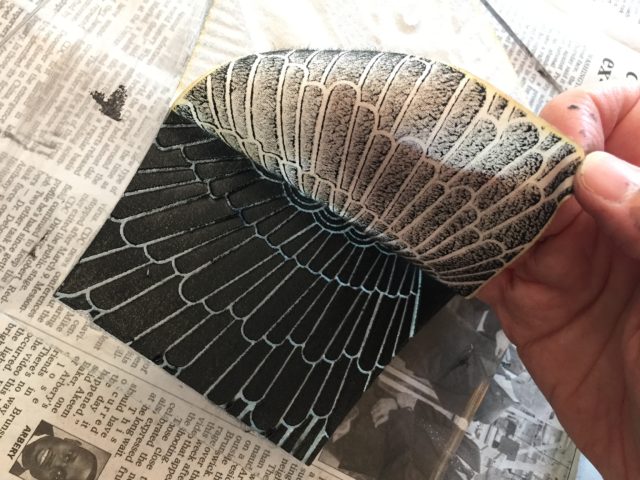

The good news is, acrylic is a perfectly viable material for block printing.

The bad news is, block printing is very labor intensive and probably not the best medium for this project. I got enough decent prints to make 3 or 4 masks out of this batch. The impression below is about the best I could do:

The screenprint ink actually worked better than the block-printing fabric ink. I applied both with a brayer. I was able to load more screenprint ink onto the block, and the fabric seemed to accept it a little better.

The image looks better on bleached white than the unbleached “natural” cotton I thought I’d prefer.

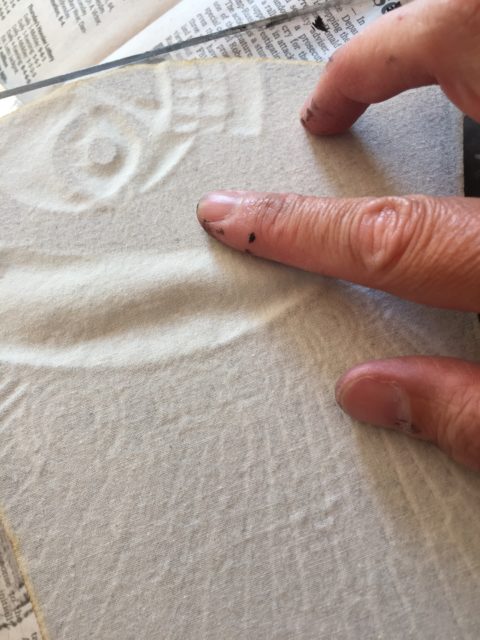

Theo made a system for registering prints on pre-cut fabric, which saves the work of cutting out with scissors later.

But it adds more labor “burnishing” the fabric onto the block with your fingers.

Impressions using this system came out lighter than my tests on uncut white fabric, even with all the finger burnishing. I’m not sure why.

The handmade, ink-textured look is hopefully charming and valuable. Maybe it’ll look cooler than silkscreen, but I’m still gonna try calling the local screenprinter again today.