The quilting and embroidery collaboration of Nina Paley and Theodore Gray is for sale and EVERYTHING must go! We hope to sell the whole business as a package. Here’s what you get:

Quilting Master IV full-frame CNC quilting robot, tables, frames, accessories, etc: $30,000 (similar retails for $50,000)

SailRite long-arm zigzag machine, table, accessories: $4,000

Brother 10-needle embroidery machine, accessories: $8,000

Threads, bobbins, etc: $1,000

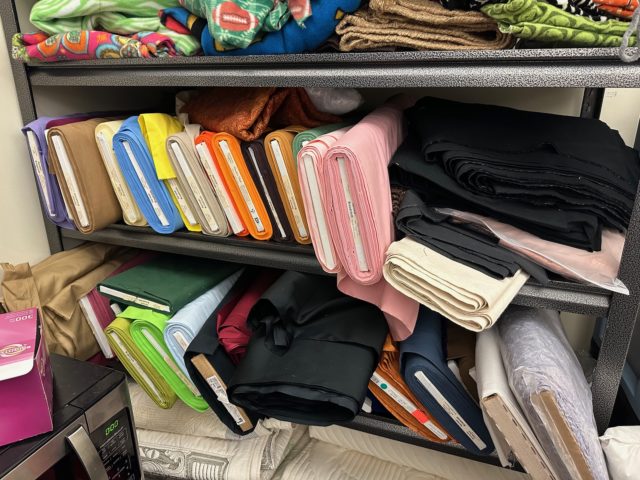

fabrics & battings (inc. extra wide): $1,000

Fabric cutter/measurer: $1,000

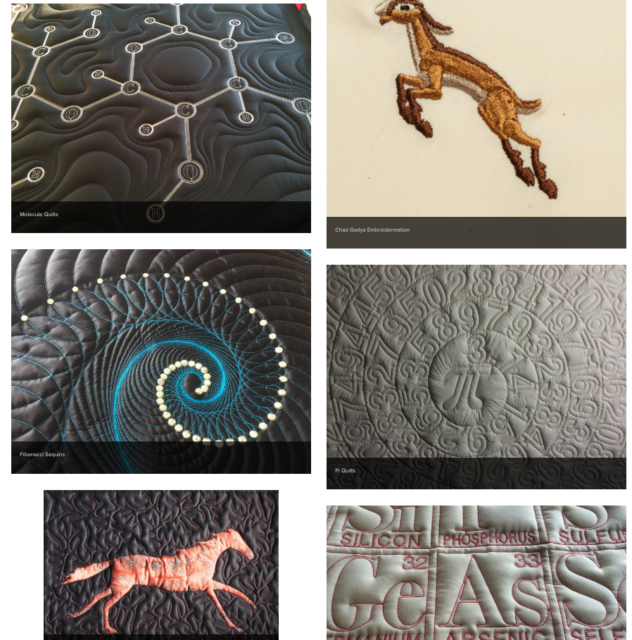

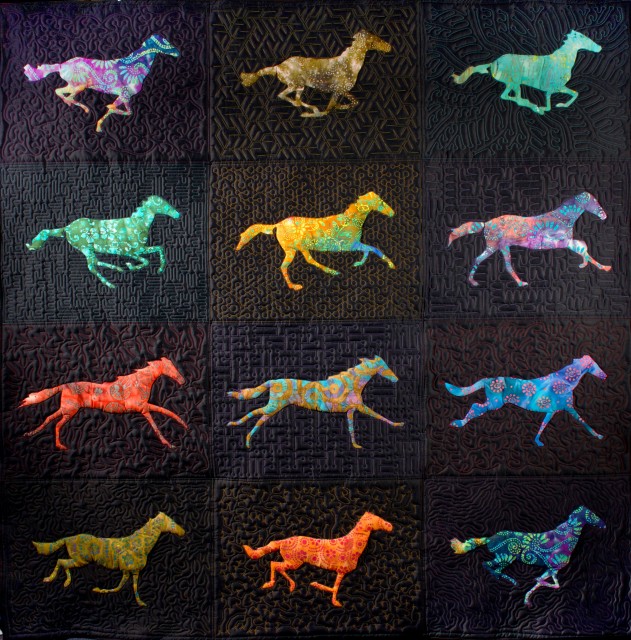

For $5,000 more, we will throw in PaleGray Labs quilting and embroidery designs, consultation/training with Theodore Gray, and disassembling and reassembling the Quilting Master machine! (Buyer covers loading, trucking, and unloading, plus lodging if destination is more than a couple hours from Urbana, IL.)

ALL THIS for just $50,000! Plus loads of extras including a wheeled stand for the embroidery machine, a serger, a barely-used 6-drawer Madiera “treasure chest” embroidery thread collection (retails at over $1,900).

It’s located at 300 S. Broadway Avenue, Urbana, Illinois 61801.

You will need at least 500 sq feet to configure these machines and tables into a functional workspace. But what a workspace you will have! The extremely heavy quilt plotter needs a solid, non-bouncy floor for stability.

Why are we selling? We lost our lease last year when our building was sold to the Champaign County Sheriff’s office and they evicted all non-government tenants. Our new space in the basement of Lincoln Square is overpriced and unpleasant, and Theo and I have become occupied with other projects. We are not giving our machines and materials the love and attention they deserve, and we have to move everything out by end of May.

Interested? Email me at