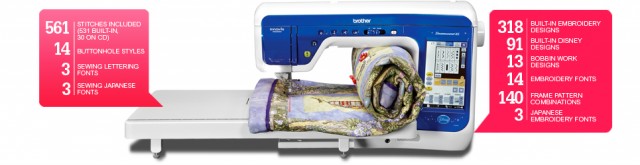

Your machines are amazing. There is so much I could do with one! I could render a vector-based animated movie, convert each frame into a simple embroidery file, and sew out a frame at a time as a quilt. It would be amazing. I want to do that so much! And your domestic embroidery machines could do it. They are reasonably priced – a few thousand dollars is quite reasonable for a machine that can do that, and many are priced even lower. Such potential! The artist in me is drooling.

But the software. For some reason you sell software for insanely high prices. All I need is software that converts common vector formats (like .eps or .ai) to an embroidery file, and allows me to size it to fit your hoops, and get it into your machine.

To do that would cost me a minimum of $900*. And is Windoze only. Brother’s PE Design NEXT (which is the minimal “level” of software I’d need for my simple vector-to-stitches conversion) appears to cost about $1,000. But I’m not sure – Brother’s web site doesn’t say, and they don’t offer it for sale online, only through “dealers.”

I understand it costs money to develop software for your machines. It also costs money to develop the machines. That’s why you sell the machines. Here’s a tip: The more useful your machines are, the more you will sell! Under the current regime of ridiculous embroidery software prices, you are selling fewer machines. I am not buying your potentially amazing machines because of the software issue. And I really really want an embroidery machine and would be happy to pay many thousands of dollars for one. I’m a ready and eager customer! But no sale.

I would buy one if I could design my own stuff for it.

Imagine a sewing machine that shipped with a limited set of licensed Disney® dress patterns, with a few more online you could download for $5 to $20 each. But sewing your own dress pattern would require expensive proprietary software, closed-source of course so it can’t be improved or debugged or customized. Or how about a sewing machine that uses only proprietary fabric? Which the sewing machine company has a monopoly on, so they sell it for $500 a yard? Sewing machines are popular and diverse because fabric is inexpensive, widely available, and can be used in any machine. The cheaper fabric is, the more sewing machines sell. Expensive proprietary fabric would mean fewer machines would sell. But that is exactly the idiotic business model embroidery machine makers have locked themselves into.

The more useful your machines are, the more you will sell!

Sewing machines are great because you can sew anything with them. Computers are great because you can make anything with them. Computers+automated embroidery machines would be great if you could embroider anything with them, but you can’t. Embroidery software for my Mac is $2,299!

Functional, accessible software makes your machines more valuable. Expensive, restricted software makes them useless.

Let me repeat: functional, accessible software makes your machines more valuable. Expensive, restricted software makes them useless. Which is a pity because they have so much potential.

*P.S. Yes I know there is Embird, which would “only” cost me $309 ($164 basic module + $145 font engine, to convert vector files) to be minimally useful for me (maybe – I can’t even be sure of that). Plus the cost of a PC (which isn’t actually that much because PC manufacturers, unlike embroidery machine manufacturers, know the value of their product increases the more useful it is, and so they encourage lots of software and even support Free Software so they sell lots of PCs, thus driving the price down further even while their manufacturers’ profits increase – think about that!) But Embird only converts EMF, WMF and CMX vector formats, so I’d need yet another program to convert a .eps sequence (or .ai or .swf) first.

There is also this Free svg-to-pcs (Pfaff) converter which I tried with this pcs-to-pes converter a few times and it didn’t work. And also doesn’t have stitch editing or further control. But it is promising.

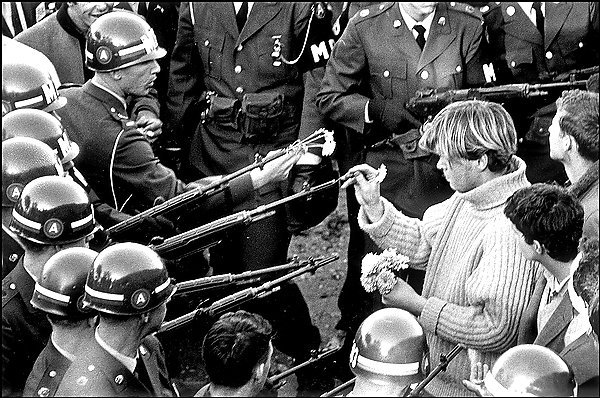

Even the mighty Linus Torvalds knows about the embroidery software problem, but it’s still not fixed.